AUTOMATION

modular Zero Employee Railyard Operations

The mobility and transport sector is experiencing critical staff shortages and serious recruitment challenges.

Automated solutions can address this bottleneck.

While zero employee railyard operation is a very bold objective, that our partners are working on with us in various research projects, it is important to remember that it is already partially realised in some hump-hunting systems, demonstrating that such a concept can be implemented. Digital Automated Coupling (DAC) is an important technological enabler for further progress.

Additional sensors and actuators as well as intelligent and safe control solutions will be needed to reap the benefits of this automation opportunity. Our work these systems will contribute to driving progress in this area.

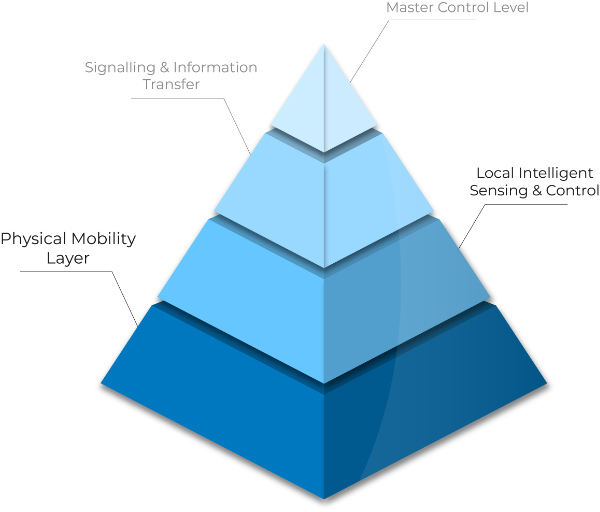

Physical Mobility Layer

Our customers’ need for zero emission performance particularly in shunting operations which are often in proximity to residential or office areas are already addressing the most important aspect of the physical mobility layer.

Zero Emission Transport Solutions

In the interests of sustainability, this movement should therefore take place with as little environmental impact as possible. Our modular zero-emission technology and solutions can make a significant contribution to this, without compromising transport performance.

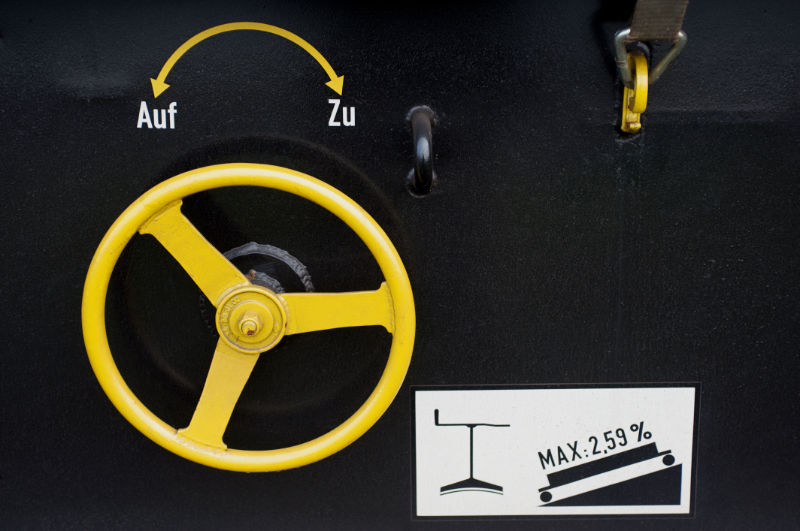

Research on Brake Systems for Autonomous Shunting

One of the key aspects of autonomous operation is the ability to safely stop and hold a moving vehicle, whether in response to an obstacle or at a pre-planned stopping point. In the rail sector, this currently requires the presence of extensive infrastructure at marshalling yards, such as beam-based rail brakes or retarders, and the deployment of additional staff at yards or on sidings in the field, responsible for manually applying hand brakes or securing the wagon with drag shoes.

However, as the potential for autonomous operation increases, as indicated by digital automatic couplers, each wagon will require an on-board power source and/or storage. This may require the development of innovative solutions. If these new options are coupled with a reliable vision system at the head of the train, there will be significant benefits for rail operators.

Local Intelligent Sensing & Control

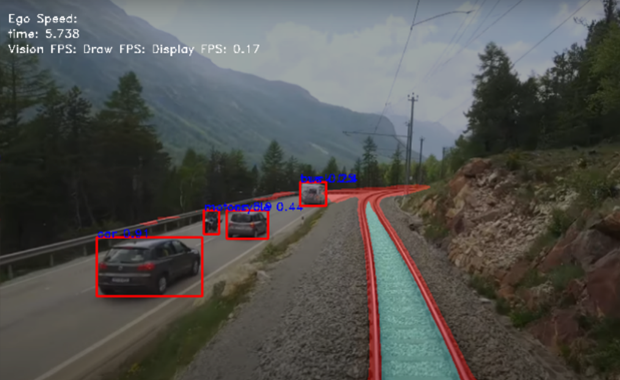

The local intelligent sensing and control layer enables safe automated process control by eventually replacing the vision and sensory system of the current train driver and the respective shunting staff.

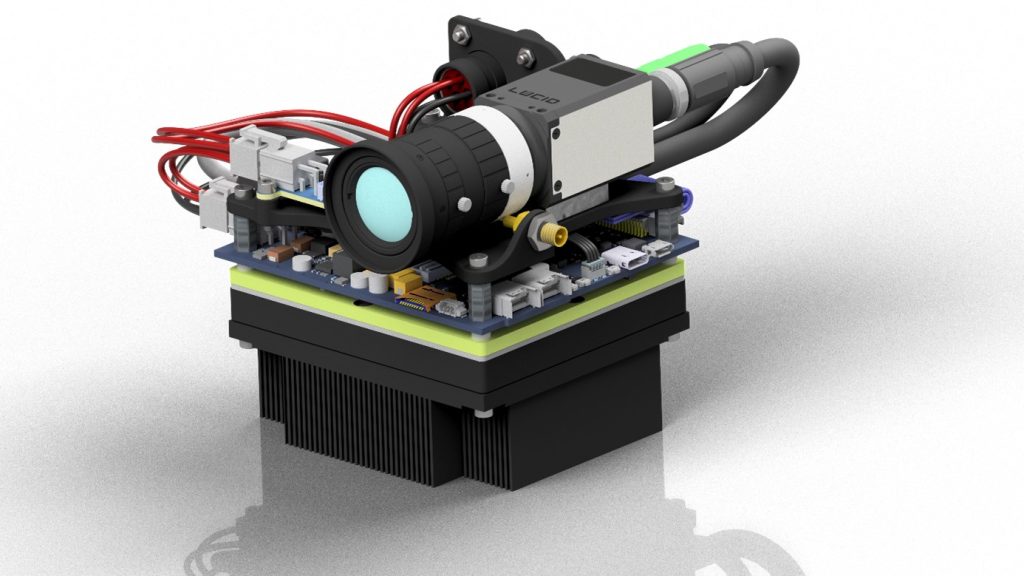

Train Head Perception System Research

Significant cost savings can be achieved in shunting or last mile operations if they can be handled single handed or fully automated via remote control. Practically and legally it is important to always have full awareness on what would be a train drivers or shunting assistants field of view to detect both obstacles and distance to shunting or loading target positions and enable the appropriate action.

We are actively involved in the evaluation and research on various sensor technologies and the related data processing to provide compact intelligent sensor suites suitable for the demanding requirements of embedded systems in off-highway applications. One example is a unit developed as part of the research programs around the application of Digital Automated Coupling. The compact unit comprises a radar, camera and various sensors as well as a high-performance computing platform. It can be easily mounted on a locomotive but may also be used a s mobile front end, if data transmission to the control system can be ensured. It accurately detects objects and obstacles in the rail vehicles operating path also enabling precise approach control.

Signalling & Information Transfer

While we are not actively involved in developing new solutions in this sector our sensor units and vehicle control systems will be interfaced using proper safety-oriented protocols. We work with leading suppliers of such solutions to create the required reliability and IT-security environment needed for successful automation of complex safety relevant processes.

Master Control Level

Working with operators and system engineers from both the research field and the industry we aim to contribute to standardized Human Machine Interfaces and smart scheduling to maximize safety and productivity of automated off-highway logistic operations.