DECARBONISATION

modular Zero Emission Repowering Options

Our modular toolkit to zero emission can be applied to all land-based vehicles. It is often an economically sensible solution in applications where the base vehicles lifetime is significantly longer than that of the primary power unit, e.g. in rail rolling stock.

Our toolkit for Operators and Fleet Users

We offer an alternative to scrapping valuable assets: zero-emission repowering as part of your next general overhaul.

For individual units or small fleets we can provide conversion engineering, including all necessary adaptations to your existing vehicle architecture and can also manage the actual conversion job.

For larger fleets, we can organise the conversion and act as prime contractor or handle quality monitoring on your behalf.

Our toolkit for OEM's

If you need help with developing new solutions without the typical diesel engine and transmission units we can assist with our modular power concept.

Our modular approach has been developed to enable OEMs to use essentially the same processes that have driven the design of their diesel units, but now using a new catalogue of units, matched by our experience and detailed simulation.

Solution Examples

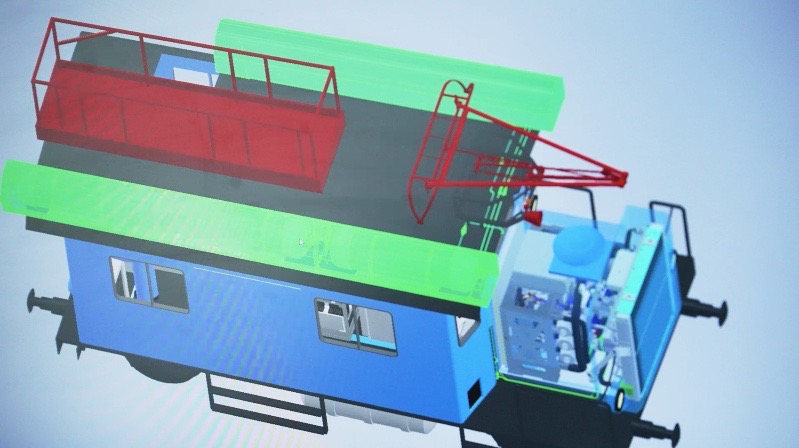

Catenary maintance vehicle

As part of cooperative research project we were the engineering lead on the conversion of a catenary maintenance vehicle (formerly ÖBB X534) which featured a diesel electric drivetrain to a zero emission rail vehicle using hydrogen, fuel cells and batteries and completely new controls. The successful integration proved that the life of such a machine could be extended significantly. The refurbed vehicle maintained and in some aspects even exceeded the original specifications but stayed within the weight limits and respected the gauge outline.

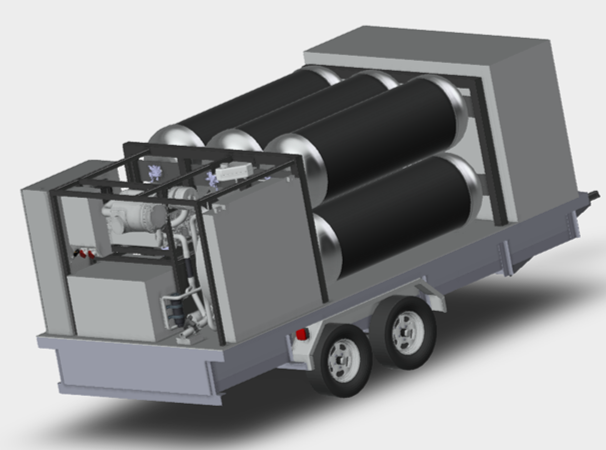

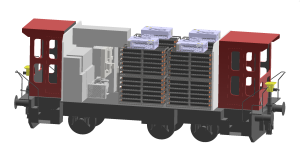

HGU-M

Clean, quiet power for the most demanding applications. Powering site lighting for long periods, charging or supplying electrical machinery or in special applications as a mobile range extender trailer or tender.

The HGU-M45 range covers a power range up to 45kWe electrical with various output voltages, typically 3AC400V/50Hz, switchable in IT or TN network environments. Additional low voltage DC supply can be integrated as well as HVDC (600-800V) for charging electric vehicles or using the unit as a mobile range extender. On-board energy depends on customer requirements but can be up to 34kg of H2 (70MPa), equivalent to a 550kWh battery.

The HGU-M100 provides up to 100kW peak power and has an on-board storage capacity of almost 103kg of H2 or approximately 1700kWh of electrical energy.

A much larger system is our HGU-M2000+, which is a mobile hybrid power plant that can be mounted on two 40′ containers and on a container flatbed truck. In this variant it can be used to power rail or marine units whose power and energy supply system can no longer be integrated into the original vehicle outline, e.g. heavy freight locomotives.

Feasibility Studies

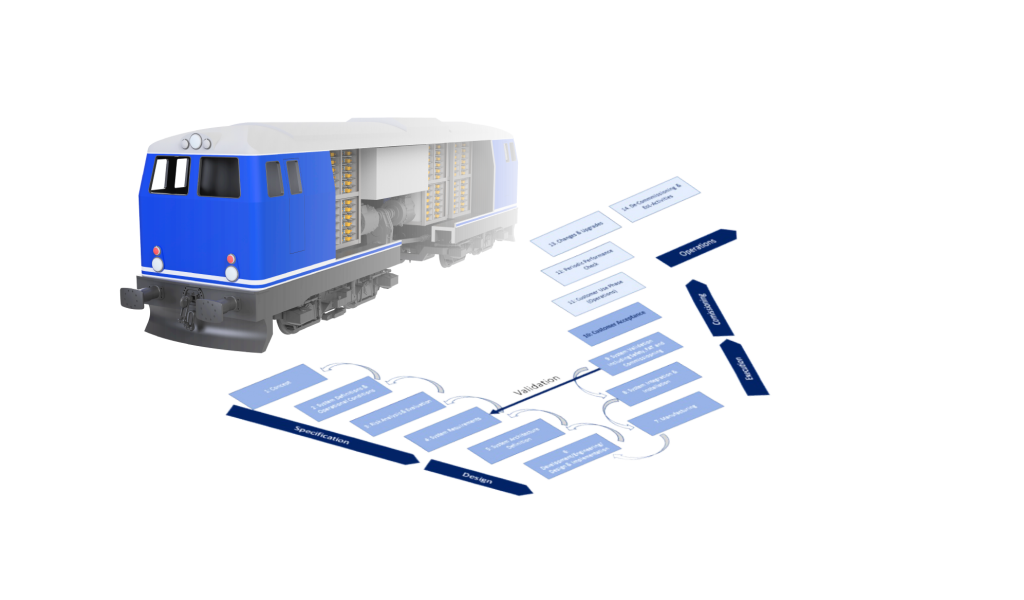

As all Zero Emission propulsion solutions, except pure catenary operation, face limitations due to on-board energy constraints, it is necessary to investigate the feasibility before embarking on a more detailed engineering project.

This effort also partially represents the phases 1-4 of the EN 50126 V-model and forms the basis for system architecture or topology decisions. Our feasibility studies typically cover the power and energy requirements derived from a simulation of the target train and the customer’s operational requirements, and an analysis of whether the required units can be fitted in the vehicle without adversely affecting operations or the approval process. It includes a first round of risk and hazard analysis and the resulting requirements. The study includes a calculation of the power supply requirements and the associated charging or refuelling infrastructure. All the technical information is complemented by a cost projection for all the necessary elements. Finally, the client is provided with an implementation framework and, for larger volume projects, a first draft of a migration plan.

Simulation

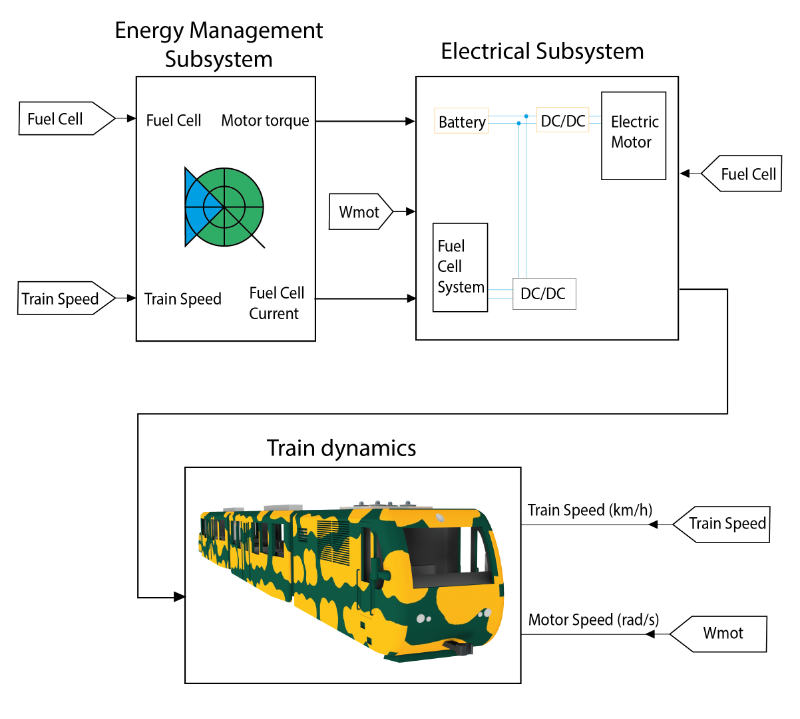

Our comprehensive simulation suite has been developed in close collaboration with simulation experts at the University of Roma Tor Vergata. It has been validated against real operating data as well as established vehicle dynamics software packages.

The simulation suite, based on MATLAB and Simulink/SimScape Elements, covers vehicle longitudinal dynamics, including cornering. It also allows the user to follow a vehicle speed profile over a given route.

The route can be sourced from digital twins of the customer’s infrastructure or developed by our own route/track module using published GIS data.

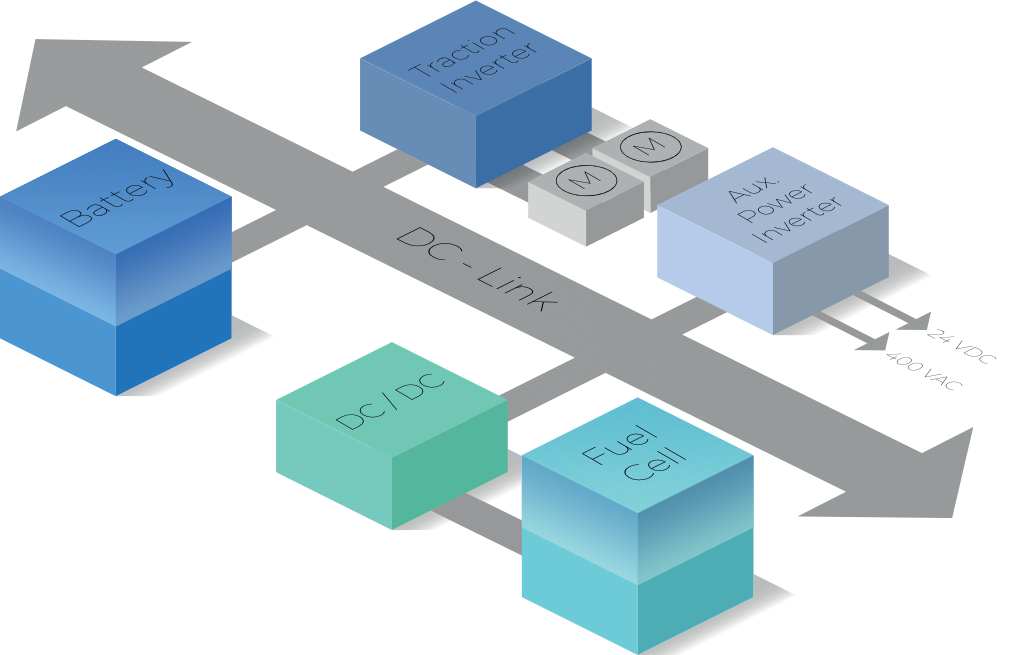

The resulting tractive force for the vehicle or train being analysed is then fed into an electric traction subsystem model as a power/energy demand. This allows us to use different electric propulsion systems, battery models and fuel cell characteristics to determine battery and fuel cell power/current requirements.

Our expertise in addressing the constraints associated with on-board energy storage in electric and hybrid vehicles has enabled us to examine key system auxiliaries and their energy consumption. In the case of fuel cells, this includes the fuel cell cooling system and, in off-highway applications, the cooling fans. It also includes items such as brake compressors and air conditioning systems.

Packaging Analysis

While the core electric traction system and its power electronics have become quite compact, one of the major differences for catenary-free operation is the still low energy density of on-board energy storage systems. Their specific safety requirements further complicate the packaging challenge. We are therefore carrying out a packaging analysis to check whether the operational concept can be implemented within the vehicle’s limits and whether the placement of the new additional components will unduly influence critical characteristics such as the centre of gravity or axle load limits. The impact on driving dynamics is also assessed qualitatively.

Energy Context Evaluation

Catenary-free zero-emission operation requires not only an on-board storage of sufficient size for the intended operating concept, but also the ability to replenish the energy at the planned refuelling or charging points. So we look at the power sources, the proximity and size of the grid and substations, the level of renewable energy that can be achieved, and other important parameters such as the availability of water for hydrogen production.

Cost Projections

We have been working in the alternative drive and energy industry for over 30 years and have developed key industry relationships. As a result, we can provide realistic cost projections for your conversion project or vehicle redesign, including medium-term cost developments. These projections include both recurring and non-recurring cost items.

Zero Emission Conversion and Modernization

This is our full service package, which combines all the services described above and integrates all these components into the customer’s vehicle with our partners.

All components are manufactured to industry standards and the conversion is carried out in a full-scale facility, such as a rail maintenance depot, which we have pre-qualified.

Naturally, such a package includes the necessary homologation and expert certification services, as well as final approval by the relevant authorities in a well-managed process with Notified/Designated and Assessment Bodies.

Finally, no new solution is handed over without proper documentation and training for the customer’s operating and maintenance personnel.

Design Services

Our services include the detailed design and selection of all components required to create a new zero emission vehicle.

This includes optimising all Balance of Plant components for the lowest possible parasitic losses, as these can affect the overall operating range of the finished vehicle. Experienced rail design engineers will consider the loads that the components will be exposed to (e.g. to EN 61373) when developing the mechanical interfaces; electrical designs will comply with the relevant electrical standards for rail or industrial vehicles.

Documentation is provided for both manufacturing and approval processes.

Key Component Supply

We offer a comprehensive range of modules and components to help you build your zero emission propulsion system.

In particular, we offer a heavy-duty fuel cell system that has been developed to the exacting standards of the rail industry and represents excellent value for money.

As the elements of our system have been developed to form complete systems, we can also source all the key components from our preferred partners.

Controls & Software

Legacy vehicles have legacy control systems, which can cause significant problems when changing to new powertrain systems. We have expert data handling and control system designers and programming resources to equip the new zero-emission vehicle with state-of-the-art controls and human-machine interfaces – always in compliance with the standards of the target operating environment.

Prototype and Small Batch Manufacturing

As an engineering consultancy, our own research and the needs of customers who wish to modernise their fleet in stages have led us to develop a prototype and low-volume production capability.

Our proximity to the engineering team allows us to provide system building blocks directly linked to their work. The team is often hands-on and closely involved in the evaluation of the assembled product.