The world wants your Diesel Assets to stop smoking.

But throwing them on the scrapyard isn’t sustainable either.

In fact, we do – at least for the off-highway sector where assets often have a lifetime exceeding that of the primary power unit which traditionally has been a diesel engine mated either to a transmission system or to generators and electric motors.

Over the years and a multitude of research projects we have developed a toolkit for zero emission mobility that addresses the needs of the two main groups affected: Operators/Fleet Users and smaller OEM’s.

These OEMs are enabled by our modular and standardized approach to basically use the same processes that has been driving the design processes of their power system design but based on simulation and our advisory replace the diesel and transmission units with the electric drive system units developed by us and our partners.

For operators / fleet users we provide an alternative to scrapping valuable assets: Zero emission repowering as part of your next general overhaul. We supply the conversion engineering including all necessary adaptions to your existing vehicle architecture and can also handle the actual conversion job for individual units or small fleets. For larger fleets we can organize the conversion and act as prime contractor or just handle Quality monitoring on your behalf.

Thus, your re-motorized vehicle assets still have many useful years ahead of them without you worrying about emission limits and accruing attractive benefits in operations, maintenance and brand image.

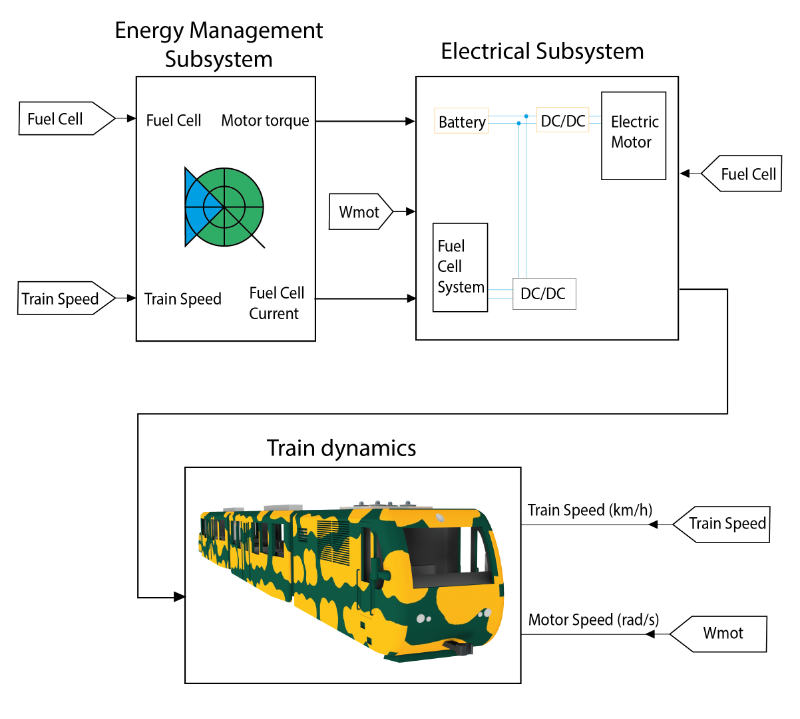

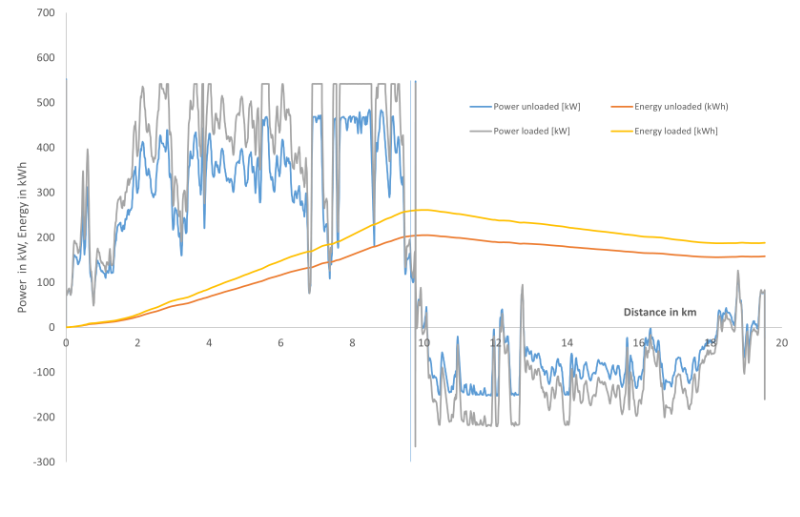

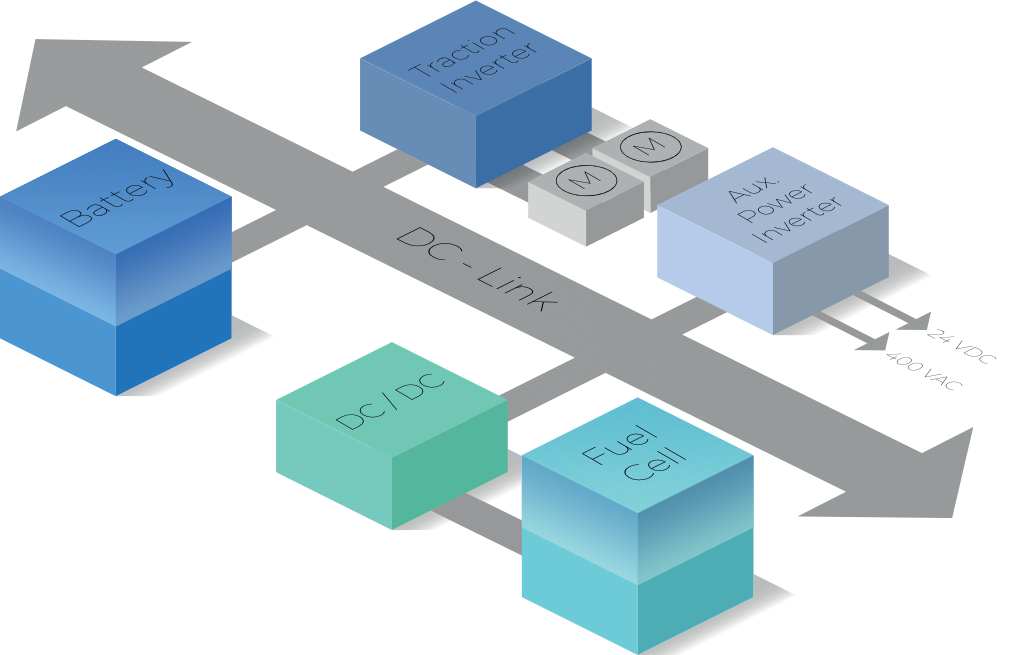

We use a complete simulation suite developed in close cooperation with the simulation experts at Uni Roma Tor Vergata. It has been validated against real operation data as well as established vehicle dynamics software packages. Based on MATLAB and Simulink/SimScape Elements it covers the vehicle longitudinal dynamics including cornering, etc. following a vehicle speed profile over a given route. The route can either come from digital twins of client infrastructure or be developed by our own route/track module using published GIS data. The resulting tractive force for the vehicle or train to be analyzed is then fed as power/energy demand into an electric traction Subsystem model, where we can use different electric drives, battery models and fuel cell characteristics to arrive at the requirements for the battery and fuel cell power/current.

A specialty derived from our knowledge regarding facing constraints with on-board energy storage quantities when dealing with ESS or hydrogen fuel cell hybrid drives is our ability to look at major system auxiliaries and their energy consumption: In case of fuel cells this relates to the fuel cell cooling system and in off-highway applications the cooling fans, but also items like brake compressors or air conditioning systems.

Feasibility studies build on the simulation block but go much further to comprise first packaging and weight balance studies and provides recommendations of a vehicle and power system architecture. A preliminary Risk and Hazard Analysis is performed given the client operating environment and corresponding technical mitigation measures are defined. If relevant and required, the supply infrastructure is looked at and recommendations are developed. Implementation is supported by a migration and project plan with the appropriate budgets and timelines, thus providing a solid comprehensive basis for decision making.

We can supply a wide variety of modules and elements necessary to build your Zero Emission Drive System. In particular, we offer a very attractive heavy duty fuel cell system developed to the exacting standards of the rail industry. As the elements of our system have been developed to form complete systems, we can also procure all major components from our Preferred Partners.

While we are a engineering consulting company both our own research work and the needs of clients who only want to modernize their fleet one step at a time resulted in our adding a prototype and small batch manufacturing capacity. Directly linked and close to the engineering team who often participate hands-on and are deeply involved in testing the assembled product we can supply those system building blocks.

This is the full-service package where we combine all the services described earlier and with our partners also integrate all those components in the client vehicle. All components are produced to meet the standards of the sector and the conversion is done at a full-scale plant, e.g. a rail general maintenance yard pre-qualified by us. Of course, such a package comes with the requisite homologation and expert certification services and a final sign-off by authorities in well managed process with Notified/Designated and Assessment bodies. Finally, no new solution will be handed over without proper documentation and training of both client operating and maintenance staff.

The H120R is a complete Fuel Cell System ready to install. We developed it due to the relative scarcity of heavy duty and particularly rail suitable fuel cell systems. It utilizes Cummins (formerly Hydrogenics) Stack systems with full rail certification. If requested it comes complete with a balance of plant package including radiator(s), coolant fans and controls (CAN) in a frame suitable for rail or similar heavy duty applications.

Various operations require clean, silent Zero-Emission on-site power. This may be for powering or charging electrical hand tools or other maintenance equipment, work site illumination during night work,measuring instruments, e.g. for noise measurement in the field or similar applications.

The power requirements thus differ according to the needs and the duration of the on-site work. Hydrogen & Fuel Cell systems offer the advantage of all the required environmental and occupational requirements while their weight is not directly proportional to energy content which can be refilled rapidly and repeatedly.

Our HGU-M 8.40 Family is a self contained modular power system designed for fuel cells with 8, 16 or 40kW of power and corresponding integrated hydrogen supply tanks, radiators, etc. Output voltages are either 3AC400V/50Hz (both IT and TN Network use, switchable) but also include a 600-800VDC outlet with programmable voltage which may be used for on-site larger battery recharging or as range extender to smaller battery vehicles.

As is well known the refurbishing of locomotives or other high-power consumers with fuel cell hydrogen hybrid technology within the existing spatial constraints is often not feasible, e.g. for main line rail locomotives having to operate daily ranges of more than 800km, a case found on many non-electrified diesel lines.

However, it is exactly on these lines that we find a dominance of diesel electric locomotives having evolved from early US-diesel designs. While supply power plants with hydrogen tank rail cars creates issues of safety due to the pressure connection between the tank wagon and the locomotive and thus difficult to achieve homologation, the case is different for a modular power or energy “tender” connected to the locomotive only via power and control cables.

For these markets we have developed our modular containerized solution consisting of a battery container with power electronics and a fuel cell system container equipped with the requisite number of our H120R modules and the necessary Balance of Plant technology which may be stacked on top of each other. The hydrogen supply then comes in the form of standard 40’ containers with hydrogen pressure vessels available from several manufacturers with total hydrogen storage of 700 to 1100kg